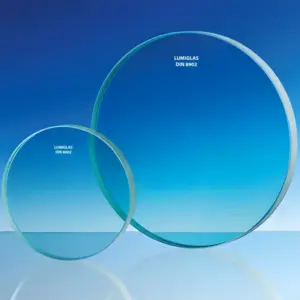

Lumiglas screwed sight glass fitting MV is designed for reliable visual inspection where a hygienic, robust welded connection and a screwed cover flange are required.

Specifications

- Weld neck nozzle material Options: 1.4307 (304L SS) or 1.4404 (316L SS)

- Slotted cover nut material: 1.4307 (304L SS)

- Sightglass Disc: Borosilicate toughened (tempered) to DIN 7080, Max Temperature 280 °C

- O-ring seal Options (product side): Silicone (FDA compliant), Viton or PTFE, Max Temperature 200 °C

- Flat Gasket (outer side): Klingersil C 4400, Max Temperature 280°C

- Operating Conditions: Pressure 6 Bar, suitable for vacuum

- Temperature limits: Fitting up to 280°C when using borosilicate glass with flat sealing face and appropriate profile seal.

- Construction: Threaded nozzle with weld neck; slotted cover nut secures assemblies; available glass and seal combinations to suit process conditions.

- Compatibility: Can be combined with Lumiglas luminaires. Lumiglas wiper type SW I fits DN 50 and larger; luminaire + wiper combination possible for DN 125.

Common applications

- Pharmaceutical manufacturing: clear, hygienic sighting for process vessels and reactors

- Food & beverage: breweries, dairies and sanitary pipeline inspection

- Laboratory mixers and pilot plants requiring secure, welded sightports

- Filters, separators and closed vessel inspection where robust welded fittings are needed

The Lumiglas screwed sight glass fitting MV offers a simple, hygienic sightport solution with welded nozzle integrity and a screwed cover for easy access and maintenance. Material options and seal choices allow tailoring to temperature, pressure and media, making it ideal for sensitive pharmaceutical and food processing applications.

Reviews

There are no reviews yet.